Related Products

|

Performance & Parameter |

||

|

Flow Meter |

Principle |

Transit time ultrasonic flowmeter |

|

Accuracy |

±1% |

|

|

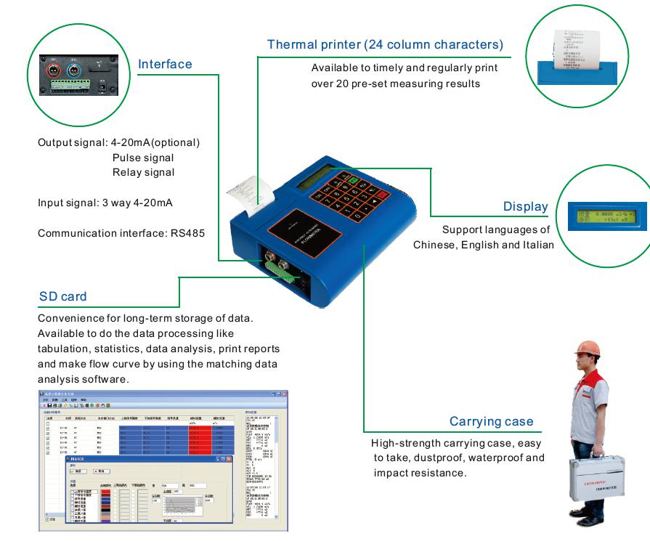

Display |

2×20 character LCD with backlight, support the language of Chinese, English and Italian |

|

|

SignalOutput |

1 way 4-20mA output, electric resistance 0~1K, accuracy 0.1% |

|

|

1 way OCT pulse output(Pulse width 6~1000ms, the default value is 200ms) |

||

|

1 way relay output |

||

|

Signal Input |

3 way 4-20mA input,, acquire signals such as temperature, press and liquid level. |

|

|

Achieve to heat measurement by connecting the temperature transducer PT100. |

||

|

Data Interface |

RS485 serial interface, upgrade the flowmeter software by computer, support MODBUS |

|

|

Data Record |

Thermal printer, external SD card(2G of capacity) |

|

|

Pipe Installation Condition |

Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed. |

|

Pipe Diameter |

15~6000mm |

|

|

Measuring Medium |

Straight Pipe |

Transducer installation should be satisfied: upstream 10D, downstream 5D, 30D from the pump |

|

Type of Liquid |

Single liquid can transmit sound wave, such as water, sewage, oil, chemicals, plant effluent, beverage, ultra-pure liquids, etc. |

|

|

Temperature |

-30~160℃ |

|

|

Turbidity |

Less than 10000ppm and little bubble |

|

|

Flowrate |

0~±10m/s |

|

|

Working Environment |

Temperature |

Convertor: -20~60; Transducer: -30~160 |

|

Humidity |

Convertor : 85%RH;TransducerI protection level:lP67 |

|

|

Power supply |

8 built-in Ni-MH batteries 1.2V(for over 20 hours of operation). Could operate 8 hours by connecting 4-20mA signal output. 90V - 260V AC adapter |

|

|

Power Consumption |

1.5 W |

|

Мы свяжемся с вами в течение 24 часов.